Automatic machine for the assembly of bars and soldering of female connectors (grouped)

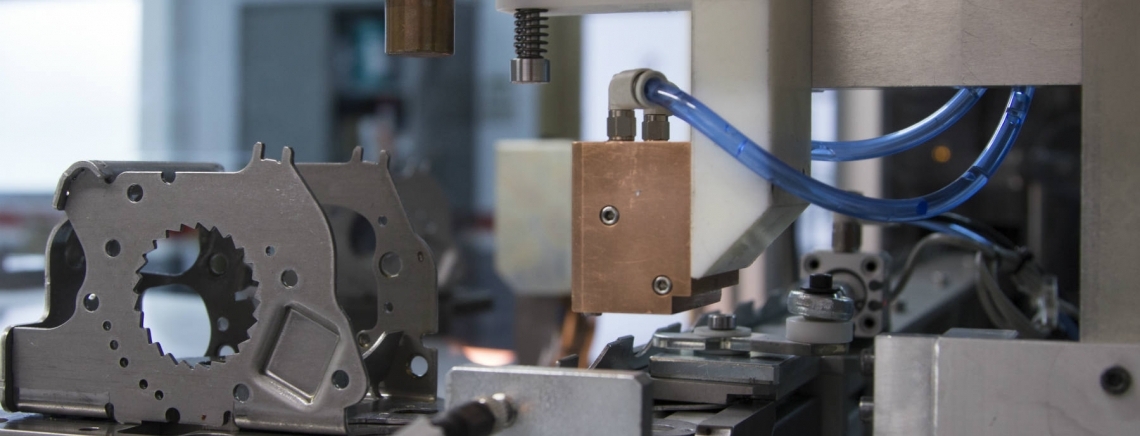

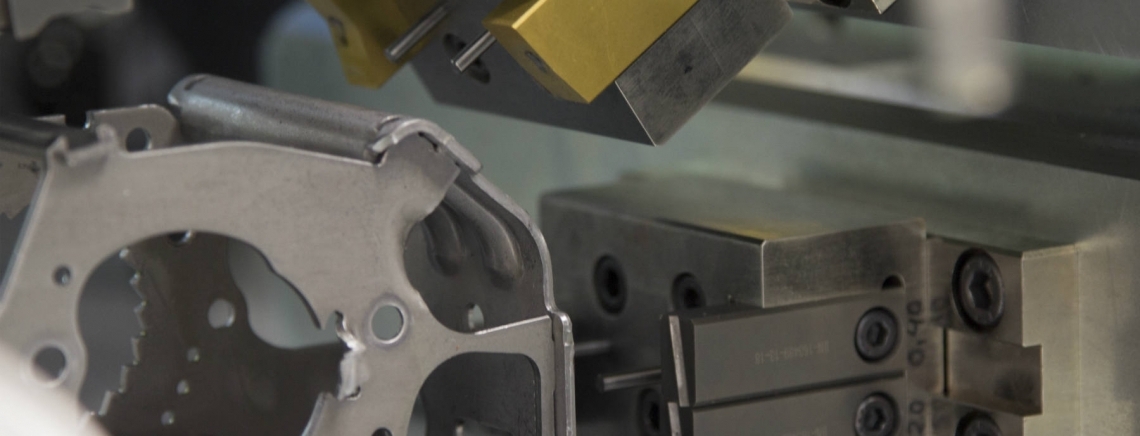

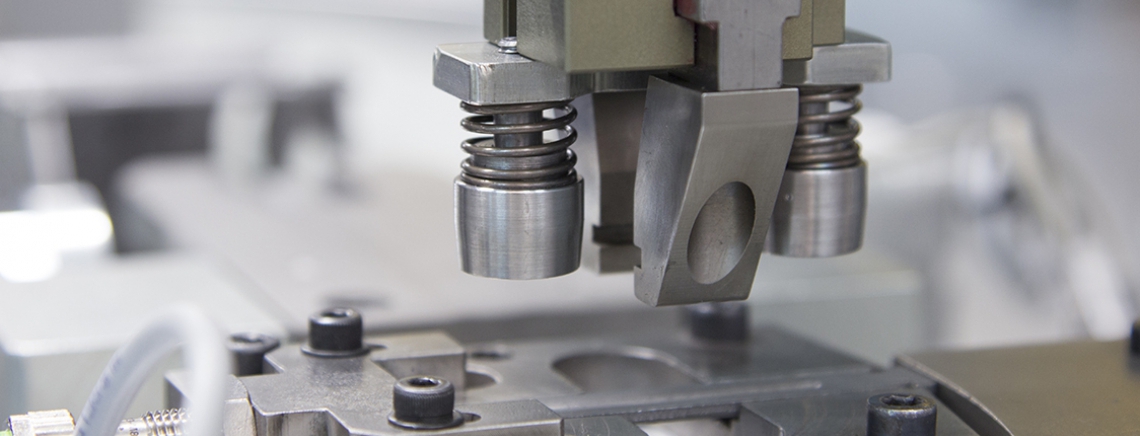

The intermittent rotary pneumatic machine is designed for assembling bars into frames. Its movements are driven by a central electric gear motor and various pneumatic and hydraulic cylinders.

Additionally, robotics and artificial vision technologies have been incorporated. It consists of 7 workstations capable of processing up to 5 different models. It includes a frame feeding station with a SCARA robot, a welding module, a thread control, a female connector control, a bar feeder with a 6-axis robot, a bar riveting station, an artificial vision inspection module, and selective extraction.

TECHNICAL DATASHEET OF THE PROJECT

Year: 2015

Technology Used: robotics, pneumatics, hydraulics

Sector:automotive

Pieces/minute: up to 20 pieces/hour

Number of Components: 4 x (5 models)

Other projects

Semi-automatic assembly benches

Semi-automatic robotic cell for packaging stamping components

PT Cover machine

Automatic machine for assembling bars and welding of female connectors and tv screen

Intermittent machine for soldering female connectors

Insertion, verification, extraction, and lubrication for inserts