Bus crimping machine

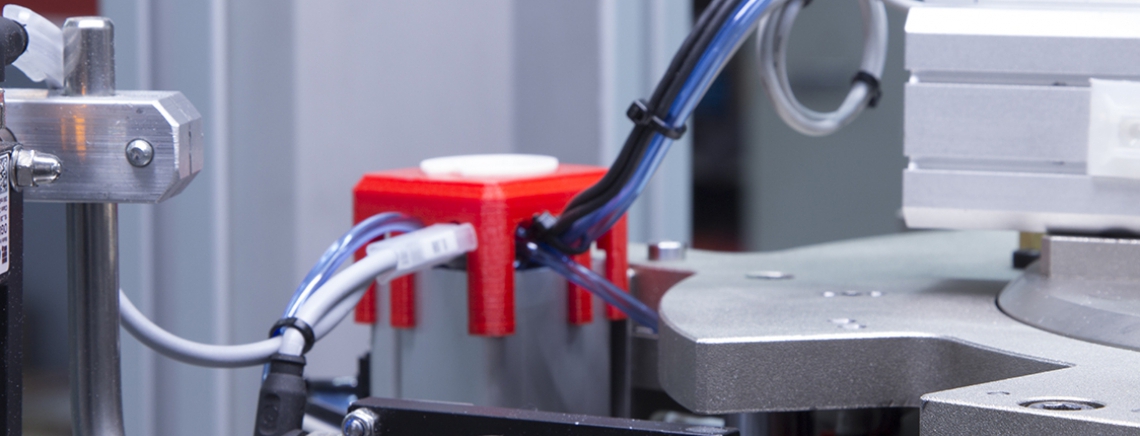

The continuous rotary machine is engineered to assemble 3 distinct diffuser models and 2 types of bus connectors. Additionally, it’s configured to manage the feeding and control of two diffuser models assembled in alternate machines, allowing for its utilization as a pill control unit.

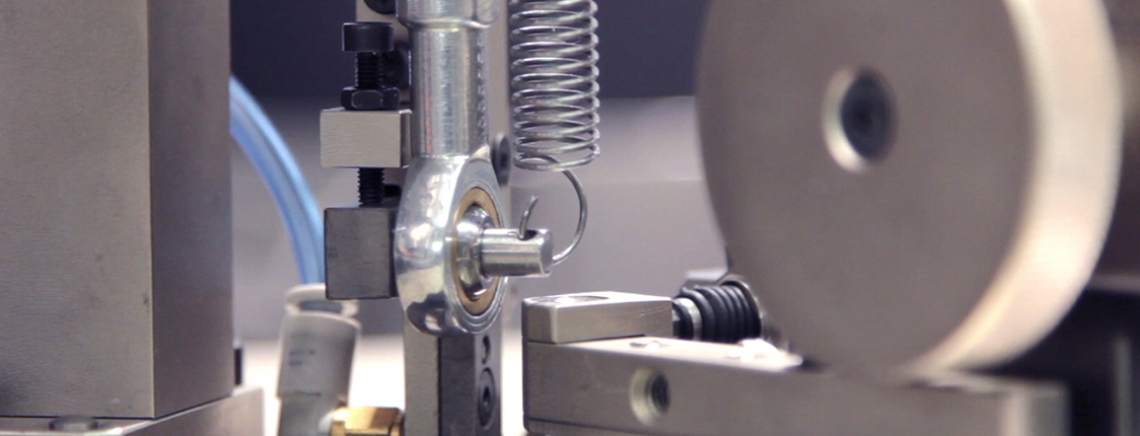

Its movements are driven by an electric reduction motor and mechanical levers. This machine pills the diffusers at a rate ranging from 100 to 120 pieces per minute.

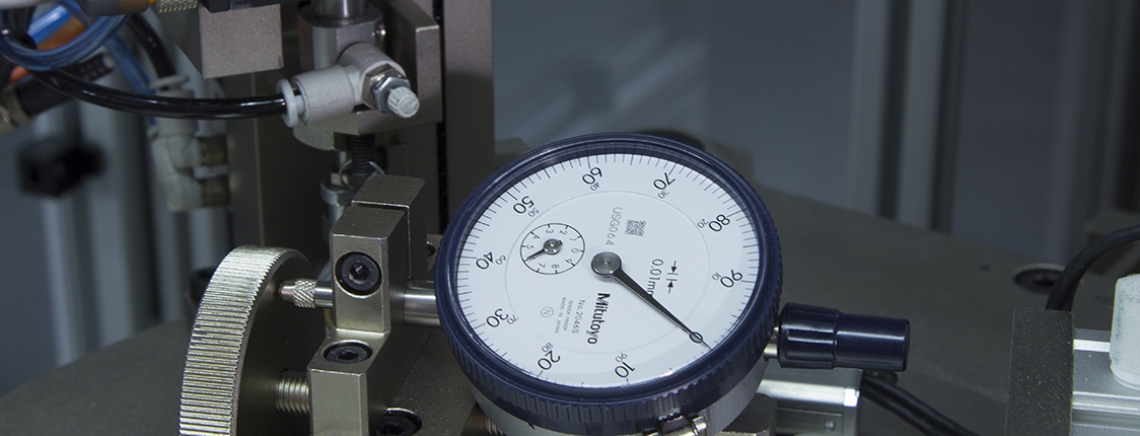

Subsequently, it conducts a fluoroscopic inspection of each assembly to ensure the quality of the crimping process.

TECHNICAL DATASHEET OF THE PROJECT

Year: 2015

Technology Used: Continuous Motion

Sector: Cosmetics

Pieces/minute: Up to 110 pieces per minute

Number of Components: 2 (3 models + 2 models) + fluoroscopic inspection