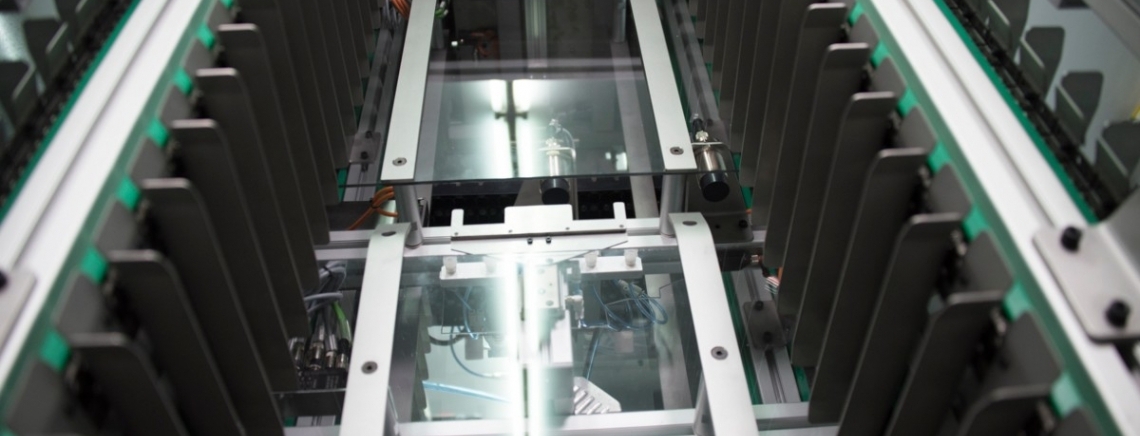

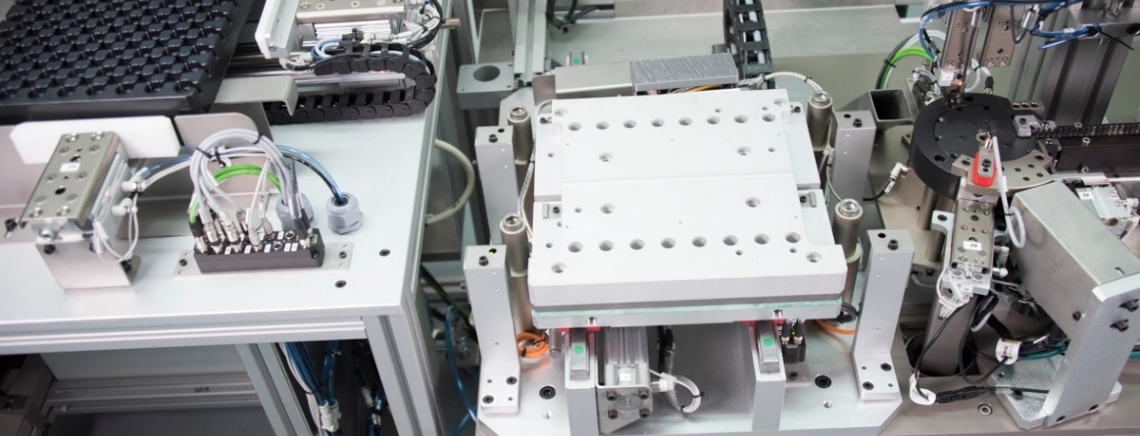

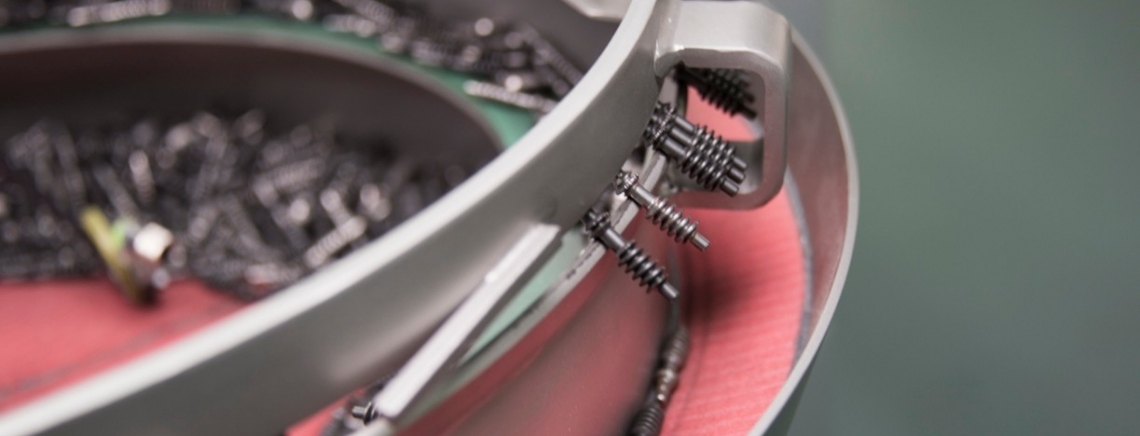

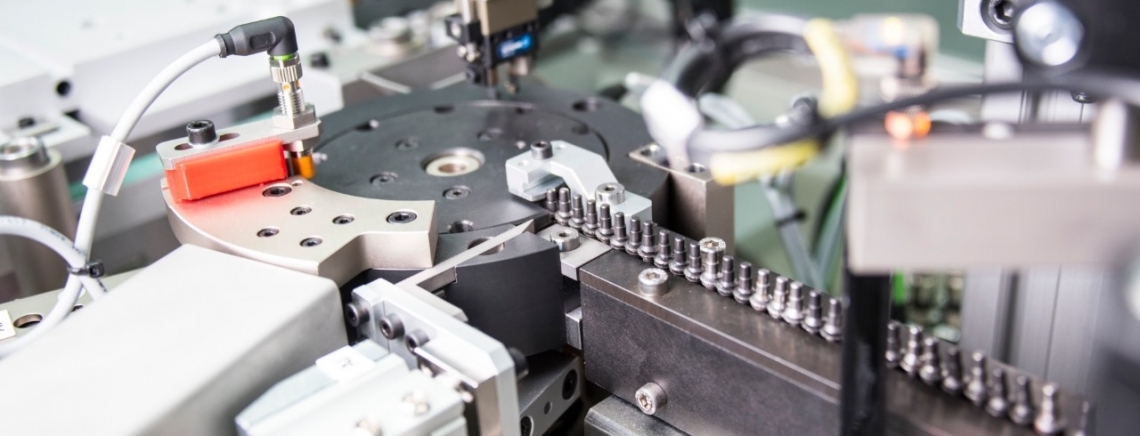

Insertion, verification, extraction, and lubrication for inserts

The machine consists of 3 stations. These stations feed inserts into an injection machine, verifying their accuracy, and then extract and lubricate the 16 injected pieces. The 1st and 2nd stations are identical, but with a different color for the produced piece, and the 3rd station differs from the other two due to the threaded passage of the piece.

In this case, the machine produces 16 pieces every 22 seconds

TECHNICAL DATASHEET OF THE PROJECT

Year: 2018

Technology Used: machine vision, pneumatics, electropneumatics

Sector: plastic injection

Pieces/minute: up to 50 pieces/minute

Number of Components: 1 x (3 different part models)

Other projects

Semi-automatic assembly benches

Semi-automatic robotic cell for packaging stamping components

PT Cover machine

Automatic machine for assembling bars and welding of female connectors and tv screen

Intermittent machine for soldering female connectors

Automatic machine for the assembly of bars and soldering of female connectors (grouped)