Inspection machine

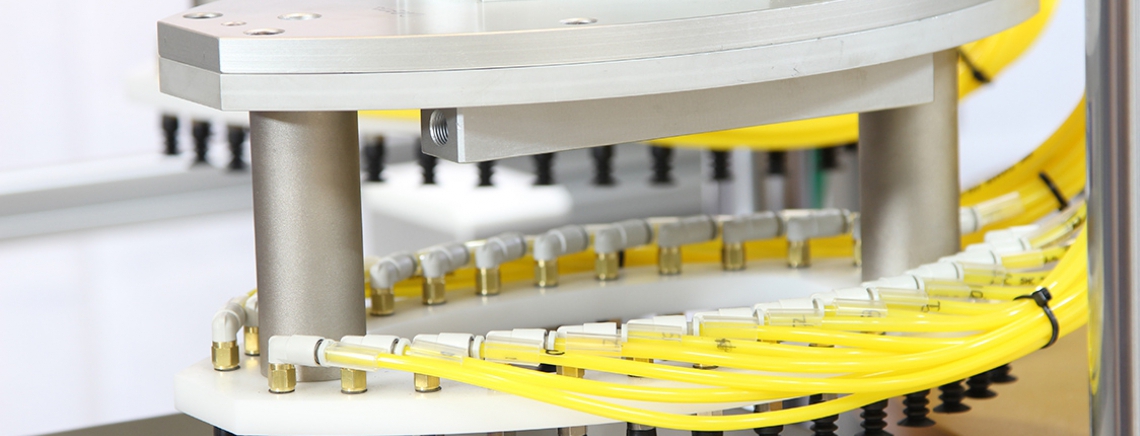

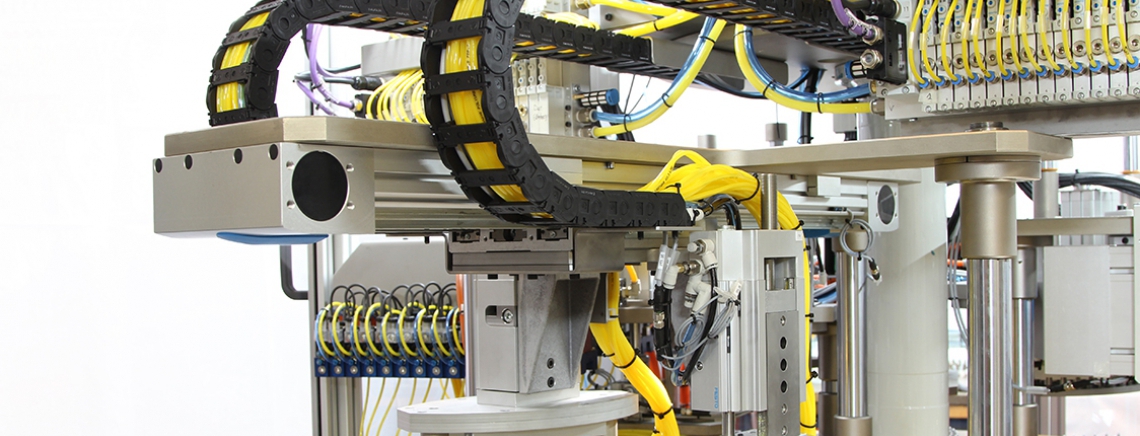

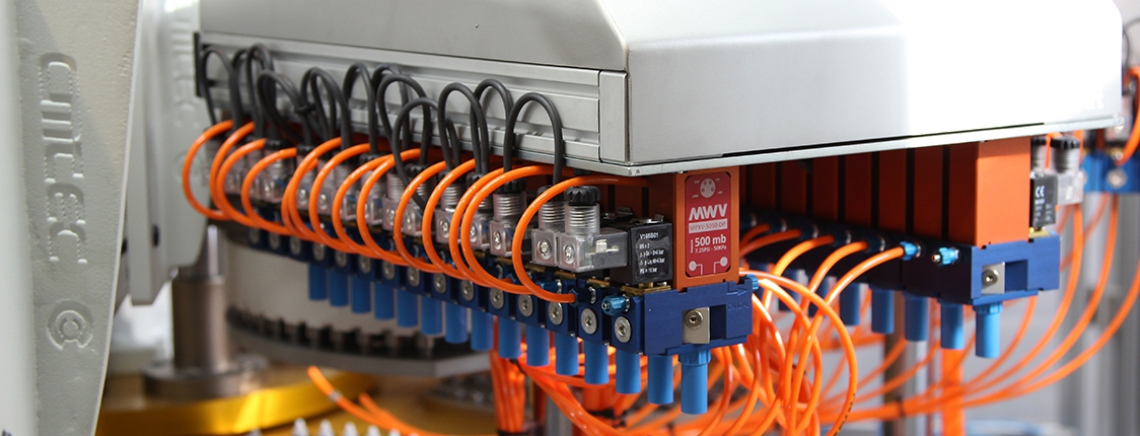

The intermittent rotary machine is designed to execute leak testing and verify the presence of all components comprising the pump motor assemblies. This project exemplifies a harmonious fusion of pneumatic and electronic technologies.

It consists of a central module, a motor feeding station, four control stations, and a selective extraction station.

At a variety of control stations, an array of pressure and suction tests are executed to evaluate the sealing integrity of the assemblies, alongside rigorous mechanical functionality assessments.

The machine achieves an impressive production rate of 560 pieces per minute.

TECHNICAL DATASHEET OF THE PROJECT

Year: 2024, 2014

Technology Used: pneumatic and electronicl

Sector: Cosmetics and Perfumery

Pieces/minute: Up to 560 pieces/minute

Number of Components: 1