Semi-automatic assembly benches

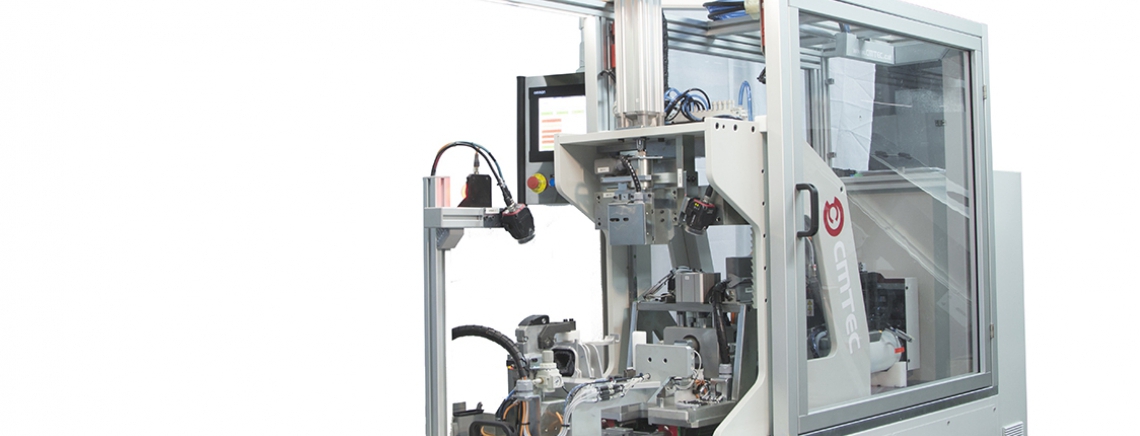

The machine is designed to assemble the engine’s silent block mounts for cars. It consists of two workstations that place special rubber pieces compressed between two moving parts to absorb vibrations and noise.

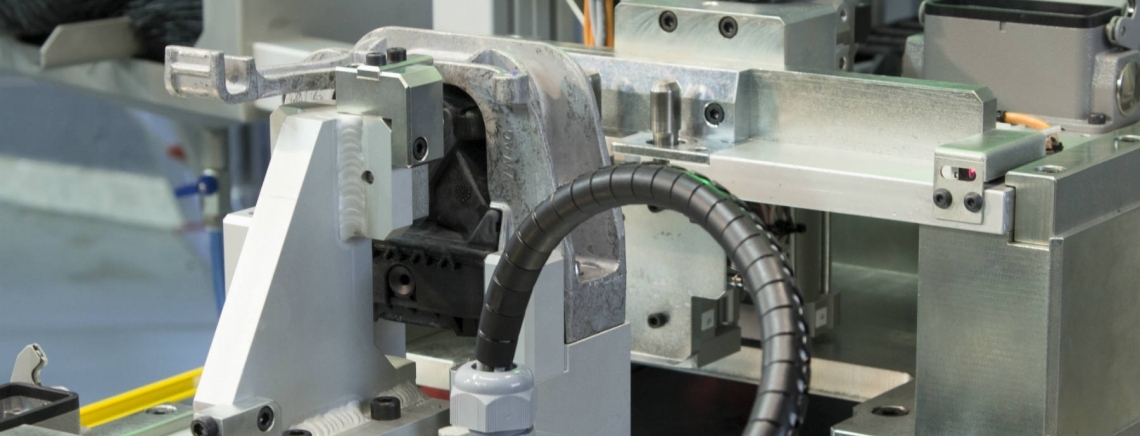

Each workstation consists of a manual component loading area, a module for verifying the presence and models of the components, a module for coupling all components using pneumatic technology, and an electronic pressing station.

For each model of silentblock, it’s necessary to change 5 interchangeable pieces per module, these are quickly interchangeable for different component families.

The predominant values inherent in this workstation lie in its utilization of artificial vision to discern the requisite model for each component and its provision for product traceability, an imperative aspect within the automotive realm for ensuring utmost safety standards.

TECHNICAL DATASHEET OF THE PROJECT

Year: 2018, 2017, 2016

Technology Used: Artificial Vision, Pneumatics, and Electronics

Sector: Automotive

Pieces/minute: Up to 5 cycles/minute

Number of Components: Multiple

Other projects

Semi-automatic robotic cell for packaging stamping components

PT Cover machine

Automatic machine for assembling bars and welding of female connectors and tv screen

Intermittent machine for soldering female connectors

Automatic machine for the assembly of bars and soldering of female connectors (grouped)

Insertion, verification, extraction, and lubrication for inserts