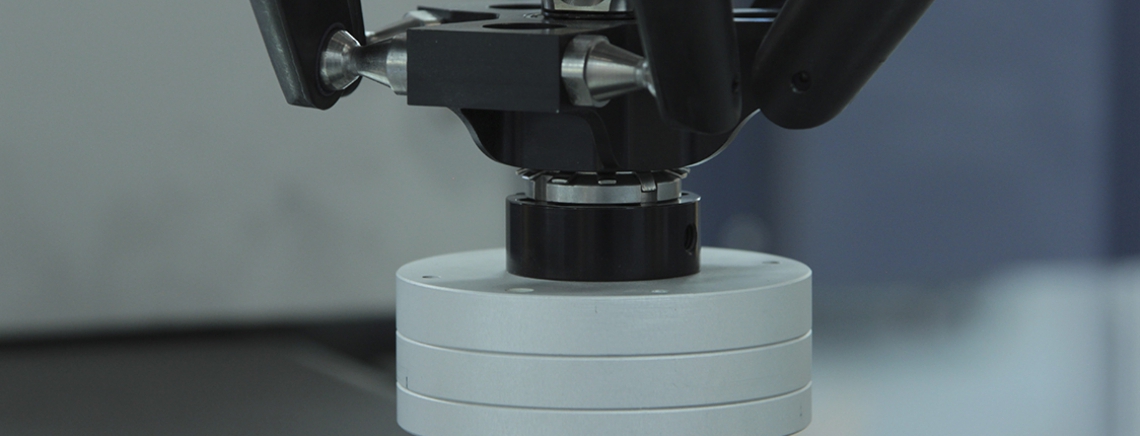

Semi-automatic robotic cell for packaging stamping components

This is a manual feeding machine designed to stack metal discs into programmable quantity columns with correct orientation.

Thanks to the synchronization of artificial vision and robotics, a high-speed precision task is made possible, which previously required a lot of manual labor, making repetitive manual tasks easy.

This project consists of 3 stations: one with a conveyor belt, another with an inspection zone for the piece’s position on the belt made by artificial vision, and finally, a spider-type robot that moves the pieces to the corresponding stacks.

TECHNICAL DATASHEET OF THE PROJECT

Year: 2017

Technology Used: Artificial Vision and Robotics

Sector: Automotive

Pieces/minute: Up to 70

Number of Components: 1 x (3 models)

Other projects

Semi-automatic assembly benches

PT Cover machine

Automatic machine for assembling bars and welding of female connectors and tv screen

Intermittent machine for soldering female connectors

Automatic machine for the assembly of bars and soldering of female connectors (grouped)

Insertion, verification, extraction, and lubrication for inserts